Project History

Petroleum Industry Operations History:

The northeast area of Greenpoint, between North Henry Street, Norman Avenue, and

Newtown Creek, has been heavily industrialized and the site of various petroleum

industries for over 140 years. Oil refining operations date back to 1834 with the

refining of whale oil. According to one published report, petroleum refining operations

began as early as 1854, with the production of kerosene, as naptha and gasoline

were considered by-products of the refining process. By 1870 over 50 refineries

were located along the banks of Newtown Creek and by 1892, the majority of the area

refineries were purchased and consolidated into the Standard Oil Trust. Around 1900,

gasoline and fuel oils became the dominant product refined or stored in terminal

facilities in the Greenpoint area. Following the breakup of the Trust in 1911, ownership

of the refinery property in Greenpoint reverted to the Standard Oil Company of New

York (SOCONY) and these operations became the SOCONY (later Mobil Oil Corporation)

Brooklyn Refinery. The refinery reportedly had a capacity to refine over 33,000

barrels (1.4 million gallons) of crude oil a day and produced fuel oils, gasoline,

kerosene, and refinery oil. Also stored within the former refinery were petroleum

additives and miscellaneous refining by-products.

Refinery operations at the former ExxonMobil Brooklyn Refinery ceased in 1966. The

refinery was subsequently demolished and significant portions of the refinery property

were sold. Several of the subdivided lots were retained by Mobil Oil Corporation,

while the other lots were sold to Amoco Oil Company (which became BP and now owned by Kinder Morgan [KM]), United Kingsway

Carpet Company (subsequently renamed Long Island Carpet Cleaners, Inc.), and others.

The lots retained by ExxonMobil were utilized as a petroleum bulk storage terminal

until 1993, when storage operations ceased at the property.

Amoco Oil Company (currently owned by Kinder Morgan [KM]) purchased a parcel of the former ExxonMobil Brooklyn

Refinery in 1968 and constructed a bulk fuel storage terminal on its portion of

the property that began operation in 1970 and which continues in operation today.

The KM terminal is 9.98 acres and has 12 aboveground and 1 underground storage tanks,

with 2 loading racks. The storage capacity of the terminal is 5,902,512 gallons

and has been used to store diesel fuel, #2 fuel oil, kerosene, gasoline, and ethanol.

In addition to the petroleum facilities on the former ExxonMobil terminal site,

the Paragon Oil Company occupied a portion of the property north of Bridgewater

Street, between Apollo Street and Meeker Avenue. Paragon Oil was purchased in 1960

by Texaco Oil, now known as Chevron-Texaco Corporation. Paragon operated a terminal

storing gasoline, kerosene, diesel fuel, fuel oil (numbers 2, 4, and 6) and lube

oil at this location until approximately 1968 when Peerless Importers (now Empire

Merchants) purchased the property and constructed a warehouse for its operations.

Remediation/Recovery History:

On September 2, 1978, the U. S. Coast Guard was making a routine helicopter patrol

of Newtown Creek when it noticed the signs of an oil spill entering Newtown Creek

from the area at the end of Meeker Avenue. A subsequent investigation concluded

that the area of the spill under the Greenpoint area was in excess of 52 acres and

the total spill volume, as estimated in 1979, was approximately 17 million gallons

of petroleum products.

The product beneath the Greenpoint spill area consist of a blend of petroleum related

liquids (oils, naphtha, kerosene, gasoline, etc). This blend rests at the top of

the water table as a free product plume, which currently is known to extend as far

north as the ExxonMobil Brooklyn terminal, as far south as the Brooklyn-Queens Expressway,

and to the west to an area located between Monitor Street and Kingsland Avenue.

The plume has impacted the soils and groundwater in both a shallow aquifer under

the former refinery properties and a deeper regional aquifer that extends outside

the former refinery areas.

Petroleum product recovery operations are currently being conducted within five

distinct areas: the former ExxonMobil Terminal, the KM Terminal, the commercial/industrial/residential

area southwest of the KM Terminal known as the ExxonMobil Off-Site Plume, the site

of the former Paragon Oil Terminal, which is currently the location of the Peerless

Importers/Empire Merchants distribution facility, and the Apollo Street Creek Parcels

located between the KM Terminal and the site of the former Paragon Oil Terminal.

Product recovery systems have been in place since 1979. ExxonMobil entered into

two consent orders with NYSDEC in 1990 and began upgrades to its recovery systems,

including the design and construction of a new and expanded system to recover free

product from the Off-Site Area. Following the discovery of free product seepage

through the facility's bulkhead into Newtown Creek, ExxonMobil also began recovery

activities at the Peerless Importers/former Paragon Oil site in February 1991. Mobil

continued recovery activities until May 2005 when Texaco took over that portion

of the project.

This

depiction is one representation of plume extent. Due to product recovery and continuing

investigation, knowledge and conditions are changing. Involved parties have slight

variations on this general depiction.

This

depiction is one representation of plume extent. Due to product recovery and continuing

investigation, knowledge and conditions are changing. Involved parties have slight

variations on this general depiction.

Remediation Methods:

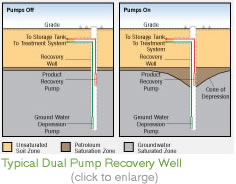

Four different free product recovery systems are currently operating in Greenpoint. These include the former ExxonMobil Terminal Recovery and Containment System (RCS), the KM Terminal Recovery System, the ExxonMobil Off-Site Plume Recovery System and the former Paragon Oil Terminal Recovery System. Significant treatment system upgrades to increase the free product recovery capacity and water treatment capabilities of all the recovery systems have been completed over the years. The ExxonMobil Terminal RCS currently includes 8 active dual-pump free-product recovery wells and a water treatment system with a capacity of up to 450 gallons per minute (gpm). The KM Terminal system includes 13 dual-pump free product recovery wells, temporary recovery operations in one monitoring well, and a groundwater treatment system with a capacity of 40 gpm. The ExxonMobil Off-Site Plume Recovery System, which was completed in 1995 as part of the Consent Order with DEC, includes 20 active dual-pump free-product recovery wells and two water treatment systems each with a capacity of up to 430 gpm. The former Paragon Oil Terminal recovery system currently consists of 16 total fluids recovery pumps that remove both product and water for subsequent separation and treatment.

Through these combined efforts, a total of over 13.2 million gallons of product has been recovered, and over 7 billion gallons of groundwater has been recovered and treated through 2024. Groundwater pumping rates (starting late 2009) have exceeded 1,000,000 gallons of groundwater per day that is treated and discharged in one of the active systems. Since 1979, the ExxonMobil and KM terminal systems have recovered over 2.2 million gallons and 3.6 million gallons of free product, respectively. The Meeker Avenue Task Force, operated by Mobil and Amoco from 1979 to 1989 at the foot of Meeker Avenue in the Off-Site Area, recovered an additional 170,000 gallons of free product. The ExxonMobil Off-Site Free-Product Recovery System, which replaced the Meeker Avenue Task Force system, has recovered over 6.9 million gallons of free product to date. In 2024, a total of approximately 31,718 gallons of petroleum products was recovered by the project.

Through these combined efforts, a total of over 13.2 million gallons of product has been recovered, and over 7 billion gallons of groundwater has been recovered and treated through 2024. Groundwater pumping rates (starting late 2009) have exceeded 1,000,000 gallons of groundwater per day that is treated and discharged in one of the active systems. Since 1979, the ExxonMobil and KM terminal systems have recovered over 2.2 million gallons and 3.6 million gallons of free product, respectively. The Meeker Avenue Task Force, operated by Mobil and Amoco from 1979 to 1989 at the foot of Meeker Avenue in the Off-Site Area, recovered an additional 170,000 gallons of free product. The ExxonMobil Off-Site Free-Product Recovery System, which replaced the Meeker Avenue Task Force system, has recovered over 6.9 million gallons of free product to date. In 2024, a total of approximately 31,718 gallons of petroleum products was recovered by the project.

Investigation of Soil Vapor and Residential Indoor Air:

On September 16, 2005, NYSDEC approved a work plan from ExxonMobil to sample soil gas at approximately 16 additional points in the Greenpoint Area around the off-site product plume. The goal of the sampling was to determine if vapors from the product plume are attenuated before impacting indoor air as believed based on earlier investigations. ExxonMobil started the investigation on September 19, 2005 and it was later completed by NYSDEC and NYSDOH. A report on the State's sampling was finalized in March 2006 and is available on the Public Documents page of this website.

The soil vapor investigation conducted by Exxon-Mobil in 2005 concluded that the free-product plume is not contributing to concentration of contaminants in residential indoor air. The depth of the contamination allowing for its biodegradation and presence of a clay/silt layer to prevent migration are factors in its conclusion. The Department has reviewed the data and agrees with the report’s conclusion; however, in order to confirm (or refute) this hypothesis, the Department conducted a residential indoor air investigation to collect the data necessary to verify this conceptual model.

During the 2006-07 winter heating season, a vapor intrusion sampling investigation was completed at 52 properties in the Greenpoint area of Brooklyn by the NYSDEC. The study area was selected by NYSDEC and consisted primarily of residential structures with some commercial operations. Sampling was conducted at structures for which property owners and tenants had volunteered and provided permission. Sampling consisted of concurrently collecting vapor/air samples from beneath the building slab, ambient basement air, ambient air from the first floor (if the basement was not used as living space), and ambient outdoor air. As stated above, a report of results is available on the Public Documents page of this website. As a result of this effort, the State believes it is unlikely that vapor intrusion from the subsurface plume is occurring in the buildings tested.

During the winter of 2007-08, the State also conducted follow-up sampling at approximately 20% of the homes included in the initial sampling. These results were consistent with the initial sampling and have confirmed conclusions draw to date. In September 2009, NYSDOH and ATSDR concluded that petroleum-related compounds in the ExxonMobil Greenpoint Off-site free-product plume area are not expected to harm people's health via the soil vapor intrusion pathway.

An assessment of soil vapor in the commercial/industrial area above the contamination has continued, with elevated levels of methane, benzene, and other petroleum related compounds known to exist around past petroleum storage and distribution operations. The Department requires ExxonMobil to annually sample permanent soil vapor monitoring points, collect outdoor ambient air samples, and screen the indoor air of buildings located within the off-site plume area to assess any potential impact from soil vapor. Notifications regarding these results have been sent to businesses in areas with potential impacts.

Since June 2010, ExxonMobil has been operating a soil vapor extraction (SVE) system at the intersection of Norman Avenue, Bridgewater Street, and Apollo Street, to mitigate the presence of shallow soil vapor contamination in this area. The SVE system has a series of wells where a vacuum is applied beneath the ground and contamination is removed as a gas and treated as necessary. Extracted soil vapor from the ExxonMobil system is conveyed to the oxidation unit located at the Off-Site Plume Recovery System building for treatment. Based on the flow rate and concentration of contamination, it is estimated that the SVE system has recovered the equivalent of approximately 172,400 gallons of free-product. ExxonMobil completed an expansion of the SVE system within OU-5 in 2015. An expansion of the SVE system in OU-7 and OU-8 to mitigate elevated concentrations of benzene and methane vapors was completed in 2016. ExxonMobil began the expansion of the SVE system in OU-5 in 2017.

At the former Paragon Oil Terminal property, Texaco voluntarily installed a sub-slab depressurization (SSD) system at the 50 Bridgewater Street building in 2010 to prevent the possibility of soil vapor migration in to the buildings. The SSD system is composed of three lateral and seven vertical extraction points, with the recovered vapors treated through two vapor-phase granular activated carbon units. Texaco also performs a monthly inspection of the floor and all the monitoring well located inside the warehouse to ensure that both are airtight to further reduces the potential for subsurface vapor migration.